Tired of Replacing Fuel Leak Detection Cables? – Reduce Costs with Reusable Fuel Sensing Cables

Do you have to regularly replace your fuel leak sensing cables?

Usually, when a diesel fuel leak sensing cable installed alongside a generator set has been in contact with diesel oil after a leak, it is contaminated and must be discarded and replaced.

The operation of replacement - such as preparation of new connections on the sensing circuit - is often complicated and time-consuming; and until the contaminated section is replaced, operation on the contaminated sensing zone is affected: identifying a new leak location could present unreliable results.

Furthermore, this kind of repetitive replacements can incur additional costs of both material and maintenance for the facility manager and owner.

In response to this problem, TTK has developed a more sustainable solution with its patented cleanable and re-usable fuel sensing cables.

Why are TTK fuel sensing cables reusable? How do they function?

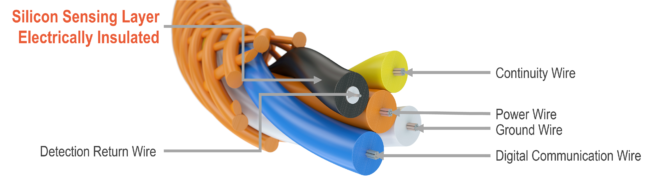

Figure 1: TTK reusable fuel sensing cable structure

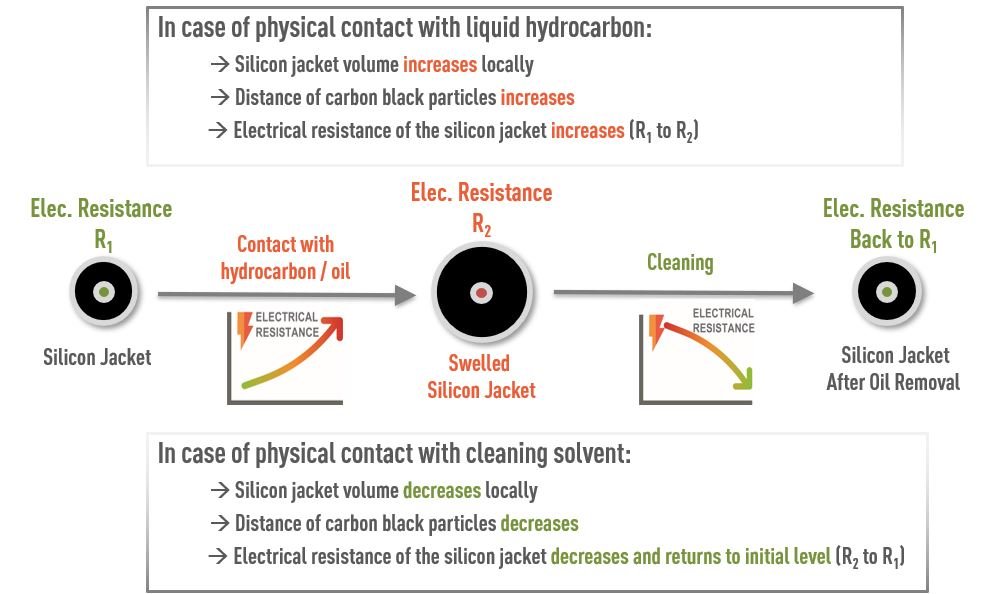

The sensing cable can detect leaks of liquid hydrocarbon on its entire length. The core of the cable is composed of a bundle of wires formed into a spiral construction. However, unlike other sensing cables using Ohm’s law, the TTK fuel sensing cable is the first cable on the market working with electrical resistance and equipped with a silicone jacket layer containing carbon black particles. When in contact with liquid hydrocarbon, it allows cable swelling quickly by absorbing all leaked liquids (see figure 2).

Figure 2: Working principle of TTK fuel sensing cable

This process is reversible meaning the cable can be reused after cleaning. The silicon polymer - different from other forms of polymer - has strong resistance to hydrocarbon, the cable returns to its initial status after cleaning, with no impact on the sensor’s reliability.

The cleaning procedure, simple to carry out and only required for non-volatile oils, consists of using an appropriate solvent to remove absorbed material from the sensing wire.

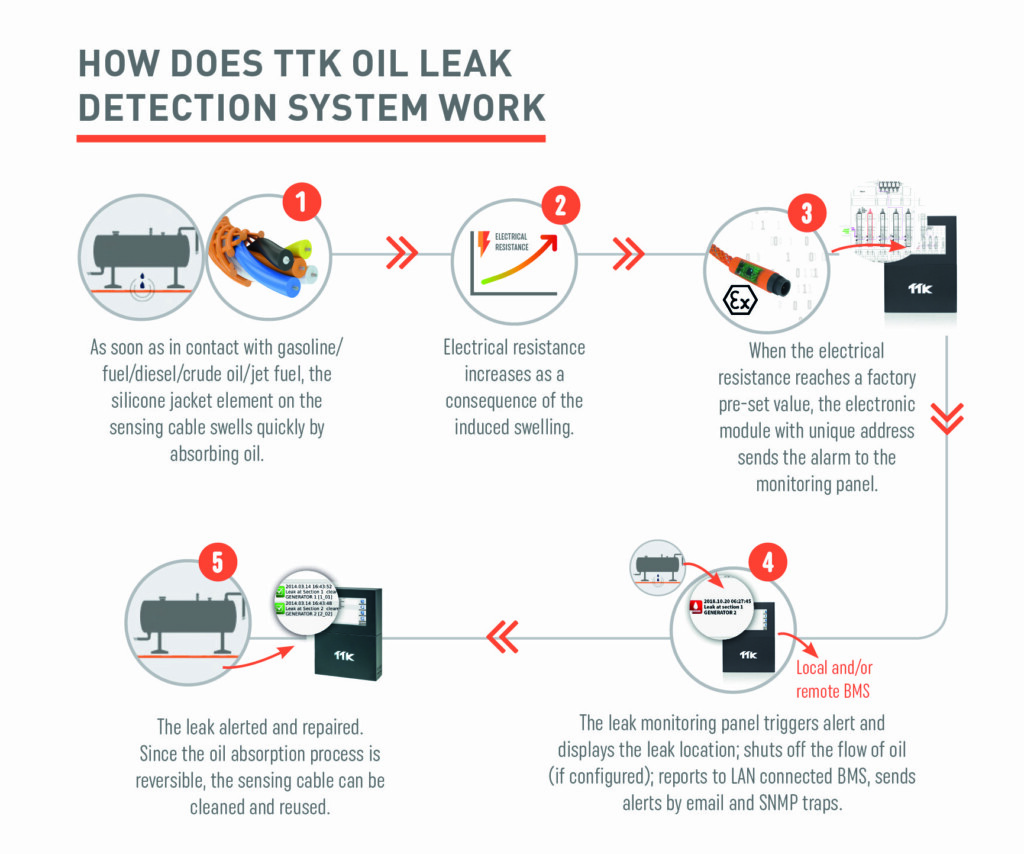

The below schematic (figure 3) illustrates how a TTK diesel oil leak detection and location system work for a generator application.

Figure 3: How does TTK diesel leak detection system work

Advantages of TTK Fuel Sensing Cables

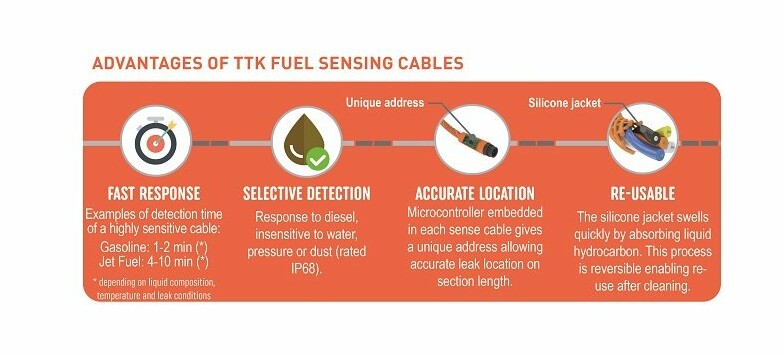

Besides drastically reducing the lifetime system costs, a reusable oil sensing cable allows clients to test whether the cable is working efficiently before installing.

The TTK fuel sensing cables have several significant advantages (figure 4) such as fast and selective detection, accurate location thanks to its unique embedded microcontroller.

Figure 4: Main advantages of TTK fuel sensing cables

Medium Sensitivity Fuel Sensing Cable FG-OD

Low Sensitivity Fuel Sensing Cable FG-ODR

High Sensitivity Fuel Sensing Cable FG-ODC

Very High Sensitivity Fuel Sensing Cable FG-ODC+

Numerous Applications

TTK fuel sensing cables are designed to be used in numerous ways for:

- Building applications – generators, day tanks

- Oil & Gas applications, perfectly suitable for hazardous areas: storage tanks/pipe networks, petrochemical plants, fuel distribution networks for airports, to provide detection of fuel leaks and to ensure safety.

Contact Us Today!

Stop discarding contaminated fuel sensing cables, save your maintenance costs and protect your generators with confidence.

The reusable TTK cable is the solution!