TTK Project Case Study: TTK in Bouygues Telecom « MOCO » Projects

TTK WATER & FUEL LEAK DETECTION SYSTEM IN BOUYGUES TELECOM "MOCO"

View the case study in PDF format.

Overview of Bouygues “MOCO” Projects

Bouygues Telecom is actively expanding its 5G network footprint across various cities and regions in France. In response to the heightened data traffic and performance demands inherent to 5G technology, Bouygues Telecom initiated a strategic overhaul of its network infrastructure starting in 2020. This initiative involves the refurbishment of existing and construction of new, state-of-the-art next-generation data centers. Over the past three years, TTK has successfully completed all existing ‘MOCO’* sites for Bouygues Telecom, totaling over fifty to date, with more in progress.

*: “MOCO” pertains to Metropolitan Office / Central Office.

Project Requirement

While each “MOCO” site has its distinct specifications, a common imperative across all is the necessity for a dependable, state-of-the-art leak detection system to mitigate potential liquid leakage risks effectively.

Monitored Areas

- Server rooms (both shared and private server rooms)

- Battery rooms

- Generator rooms

- Optical rooms

- Transformer rooms

TTK’s Solution

Within the numerous sites completed for Bouygues Telecom by the TTK France team, we’ve singled out a specific site for this Case Study.

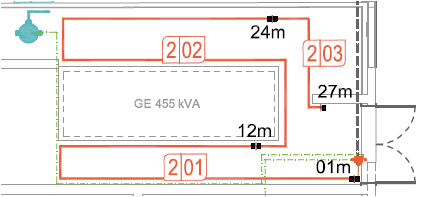

Generator Room:

In the generator room, a TTK Fuel Leak Detection System is operational, continuously monitoring the generator set. Three lengths of fuel sensing cable (reference FG-OD) are installed

around the equipment.

|

|

Microchip embedded Addressable fuel sensing cable: FG-OD

Following a thorough site audit, TTK France recommended adding a water point detector on the condensate tray for early detection of water presence. This proactive measure supplements fuel detection efforts. Both the sensing cables and the point sensor are integrated into the FG-NET leak monitoring panel, ensuring seamless and consolidated monitoring.

Example layout of diesel leak detection cables and water leak detection sensor in a generator room

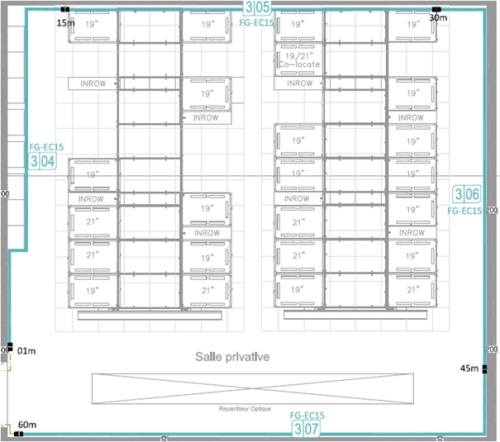

Server Room:

In the server room, TTK’s FG-EC water sensing cables are strategically positioned along the room’s perimeter, enabling efficient monitoring of water leaks from outside the space. Similar configurations are implemented in battery room and technical area, such as optical room, transformer room, and HV/LV switch room.

Example layout of water leak detection cables in a server room

The choice of FG-EC addressable sensing cables is based on their advanced features facilitated by the embedded microcontroller. Their distinctive “dust-resistant” cable structure effectively prevents false alarms caused by dust, condensation, or metal particles, providing operators peace of mind.

FG-EC addressable water sense cable

Moreover, each individual cable within the same output operates independently, unaffected by the status of preceding or subsequent cables. The monitoring panel can manage each cable independently, enabling the detection of simultaneous leaks within a single detection line.